-

Spurty’s Mechanical partners with Endurequip Hoists

October 25th, 2023 | by endurequipOversized trucks can be difficult to service. The equipment needed for such trucks is different from that of a regular heavy vehicle. It is hard to find good equipment and harder to service and maintain. The challenge multiplies when you are in a remote area because the service charge to maintain and repair the equipment can be astronomical.

Being in the heavy vehicle lift industry for over 35 years, Endurequip is aware of these challenges faced by businesses and when Spurty’s Mechanical reached out, we worked together to find the perfect solution.

The Challenge

Spurty’s Mechanical provides maintenance and repair services to trucks and other heavy vehicles. Located in Kalgoorlie, WA, a hub for the trucking industry where oversized trucks frequently stop for repairs and servicing. The remote location meant that Spurty’s was seeking equipment that would stand up to the harsh terrain, red dust, and environmental conditions of Western Australia.

To service the oversized trucks and trailers, they needed hoists that were:

- Reliable and proven in the industry.

- Easy to maintain, with little downtime for maintenance.

- Quality build to ensure the safety of their employees, which was a key priority for the business.

The Solution

Spurty’s Mechanical started searching for new and used equipment and reached out to us, aware of our reputation in the industry.

They researched the option of battery-powered Bluetooth hoists but realised that these were prone to syncing and bandwidth issues, meaning that trucks could face the risk of potentially being stuck on the lifts. This could result in unplanned downtime and a loss of productivity when the issue is rectified.

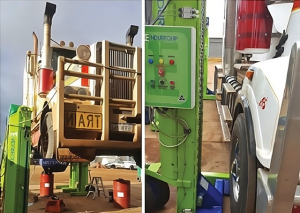

With emergency stops and safety locks, Endurequip Hoists were a primary choice. Our simple operation with reliable RUD chain technology and an authorised service network in WA meant ease of convenience and faster accessibility should any maintenance issues arise. It was a win for a busy repair and service shop that wanted to concentrate on its core business, repairing trucks.

Flexible Customer Terms

Our financing partner, A Class Business Finance, also offered a flexible financial plan to help with the purchase of hoists and other workshop accessories. We set up the commissioning and installation quickly, allowing them to get a jump on the trucks waiting in the shop.

The Results

Endurequip Portalift Hoists has made it easy for Spurty’s to work efficiently and quickly. The ease of access to the truck to replace or access large parts makes their jobs quicker and safer. It also offers the mechanics more time to fix the truck than on the hoists.

Paul Szolkowski from Spurty’s Mechanical said, “These hoists are exactly what we were looking for. The portability and easy use with just one man has lightened the load in our shop. The hoists are easy to use, safe, and can handle the harsh outdoors that we subject them to. Endurequip really came through for us.”

Spurty’s have extended their Endurequip range with the purchase of two more hoist posts and other workshop accessories.

Without Trucks, Australia Stops! But when trucks need to go, Endurequip keeps them going!

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors, inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

-

Lifting Solutions for Buses and Coaches

August 3rd, 2023 | by endurequipThe only Australian-Made Portable Heavy Vehicle Hoist

It takes something pretty special to lift the wide variety of buses and coaches around Australia. When it comes to servicing the industry’s fleet of vehicles, one of the safest ways to do so is by using an Endurequip hoist to lift a bus off the ground. In the world of hoisting, Endurequip Hoists has a few firsts that make it a unique option for the local market. Endurequip is featured by the Australian-Made Organisation as the only portable heavy-vehicle hoist made in Australia.

Manufactured in Brisbane at a state-of-the-art 6,000 square metre factory, the hoist is also the only chain-driven heavy vehicle model of its kind. Endurequip has been trusted by Australians to provide heavy vehicle lifting solutions for more than 35 years, with its range of products helping lift the heaviest of vehicles, including Australia’s buses and coaches.

One Stop Workshop Lifting & Handling Solutions

Outside of its well-known Portalift Hoist, Endurequip also offers workshop lifting and handling solutions to the heavy industry, public transport, logistics, mining and rail industries. It does this by providing a wide range of vehicle ramps, A-frame trailer adaptors, vehicle stands, transport frames and mobile gantry frames to customers all around the nation.

When it comes to the Endurequip Portalift Hoist, each hoist has a high load capacity that can lift up to 7.5 tonnes. If used in a combination of four, six or eight posts, this hoist can lift vehicles that range in weight from 30 tonnes to 60 tonnes, giving customers a versatile solution that can shoulder the burden of vehicles from the light rigids to the prime movers and the heaviest of coaches.

Endurequip is also versatile – it can offer a higher load hoist that goes beyond the weight grade of buses and coaches, lifting rail locomotives instead. The company spans across multiple sectors and is the supplier of the only heavy vehicle hoists trusted by the Australian Defence Force (ADF).

The Endurequip Portalift system is designed to be long-lasting and offered with hoist and gearbox covers, protecting the system from any dirt or grime that can mess up a Portalift system. Throughout this entire product process, Endurequip offers customers structural manufacturers’ lifetime warranty on the Portalift that includes on-site service and authorised service centres Australia-wide, minimising downtime of the hoists and also making service workers feel safe when operating around lifted buses and coaches.

Trusted by bus and coach manufacturers

Endurequip has a rich history in bus and truck workshops around Australia, with customers including Nexport. Endurequip has been supplying hoists to the designer, manufacturer and distributor since back in its Gemilang days emanating in Ballarat, Victoria in 2009. Having manufactured more than 300 buses, Nexport has turned to Endurequip hoists to continually service its fleet in Australia and New Zealand.

As a local company, Nexport was keen to use another Australian-made brand, especially when it discovered Endurequip could provide a set of four hoists rated up to 30 tonnes that exceeded weight requirements and ensured safety was top of mind. Endurequip vehicle stands also allow the Nexport team to access and work on various machines, with Endurequip workshop lifting and handling solutions helping Nexport to deliver many buses meeting Victorian government needs.

Through a range of one-stop parts and accessories packages that include vehicle ramps, A-Frame trailer adaptors, small-wheel adaptors and engineered solutions, Endurequip can provide a unique solution that makes servicing and maintaining buses easier than ever before

Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

-

Brisbane Truck Show

April 24th, 2023 | by endurequipEndurequip Hoists will be displaying workshop lifting and handling solutions in the Brisbane Truck Show from 18-21 May 2023 at the Brisbane Convention Centre.

Visit us on Stand #380 in the Plaza Level to discuss how RUD and Endurequip can assist you with your lifting and handling solutions. Come and check our products:

- Endurequip Hoists – Australia’s most trusted and the only Australian Made portable heavy vehicle hoist

- A-Frame Trailer Adaptors

- Vehicle Stands

- Tyre Protection Chains

- RUD Lashing Solutions

Book your Brisbane Truck Show tickets here.

Without Trucks Australia Stops. But when trucks need to go, Endurequip keeps them going!

-

Importance of load securing in vehicles – Part 2

March 28th, 2023 | by endurequipContinued from Part 1 on THE IMPORTANCE OF LOAD SECURING. Click here to read Part 1.

Tie-down Lashing

Tie-down lashing is the most common type of lashing for the transport of goods over the road. If the cargo is wide (if not wider than the truck tray), securing the load is only possible by vertical or slightly inclined tie-down lashing.

In the case of tie-down lashing, care must be taken to consider factors such as:

- High friction between the load and the load surface (cargo and the truck).

- Knowledge of the vertical angle which should be as close as possible to 90°.

- The load must be able to cope with a higher pre-tension.

- The lashing points must be suitable for the load.

- The amount of pre-tension force to be applied using the tensioning element should be known.

Note: Tie-down lashing only works if there is enough friction between the loading area and the load. For example, a steel load on a steel loading area does not offer enough friction which is why wooden supports or anti-slip mats should be used to increase friction.

Diagonal Lashing

For diagonal lashing, two angle plans (horizontal and vertical) should be considered and two angles defined. Diagonal lashing should be prioritised over tie-down lashing. This is because with diagonal lashing, the lashing equipment is not subject to pre-tensioning forces. The lashing equipment is only subjected to higher loads in the event of sudden braking, jerky start, or close cornering.

Are Lifting Points suitable for Lashing?

Lifting points are often installed for lashing purposes. However, lifting points are used primarily for lifting and therefore not marked with the permissible tensile force LC (Lashing Capacity – daN) but with their WLL (tonne). It is important to know that lashing points and lifting points are subject to different design factors. This is why you will find it easier to meet practical requirements with high-strength, tested, and field-proven RUD lashing points.

Weldable RUD lashing points are forged and available in blocks that can be easily welded. RUD lashing points with LC specification in daN can also be retrofitted to the vehicle carrier by certified welders. In addition to these weldable lashing points, RUD also offers an extensive range of boltable lashing points which can be used for load securing.

Tips for Skip Loaders – Optimum Load Securing with Angled Lashing

Load securing is always about the safety of people and the load. Also, having your load secure ensures that you do not run the risk of fines by the transport authorities. With RUD lashing products you be assured of safe transport of your cargo all the time.

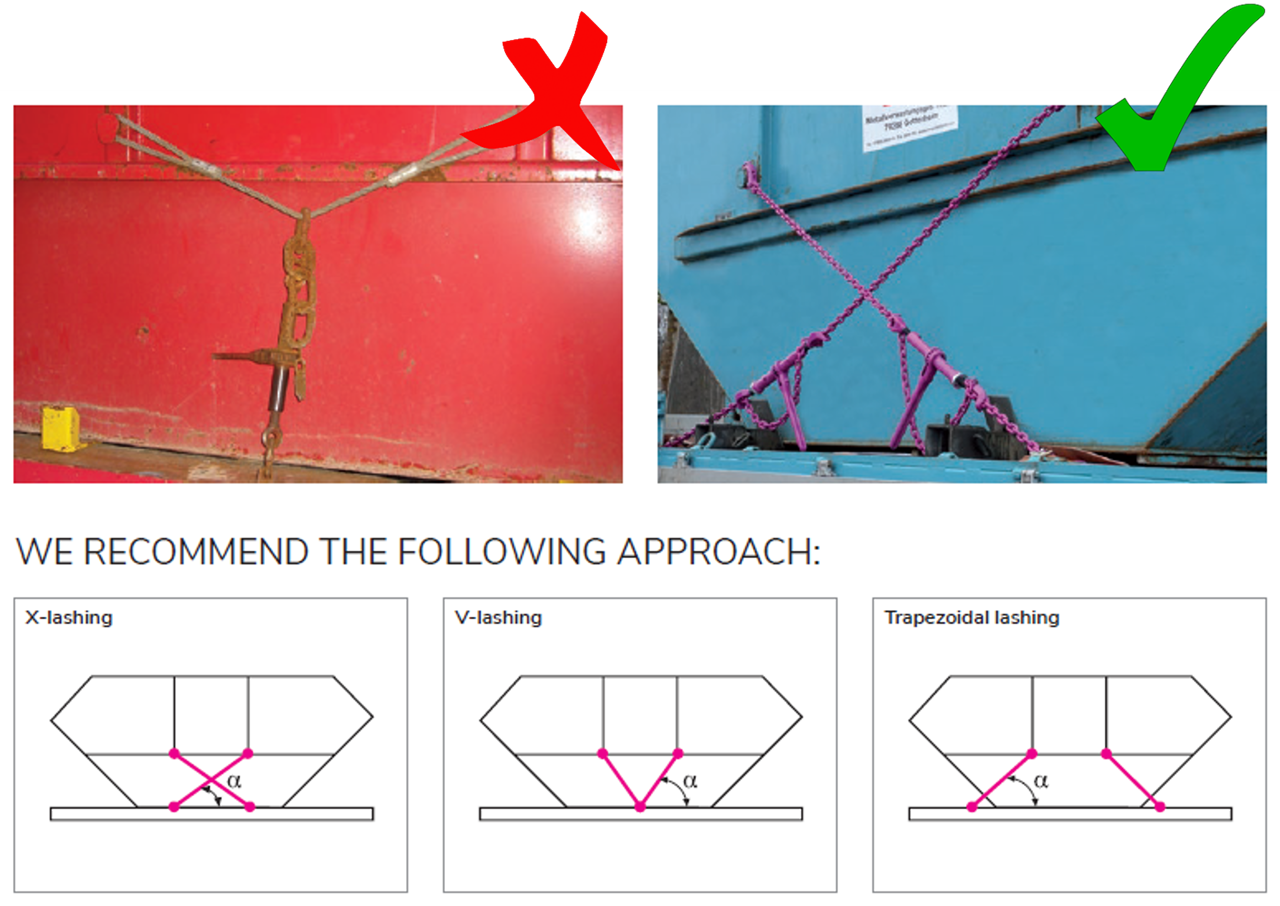

As shown in the pictures, tie-down lashing of trough containers is advisable in V, X, or trapezoidal angles with a fixed connection at the lashing point and the suspension pin. A Y lashing should be avoided because the load will not be adequately secured with this type of lashing.

Finally

If you are transporting heavy machines or cargo, it is important to plan load securing during the design phase components. This means, installing lashing points on both the load and the loading area.

Some of the points to note:

- Lashing points should be freely accessible.

- The lashing point shape should allow the folding safety catch of the lashing hook to be closed.

- Lashing points should be adapted to the shape of the lashing hooks and should not require any additional adaptor elements such as shackles.

- Lashing points should guarantee the correct load of the connected lashing hook (load at the bottom of the book / no bending load).

- The positioning of the lashing point should allow lashing in the direct strand without lashing redirections over component edges.

- The positioning of the lashing point should make it possible to maintain reasonable lashing angles.

- Lashing points should be marked with their permissible lashing capacity.

- Lashing points should be available in sufficient numbers and tensile force.

- Lashing points should be easily replaceable in the event of damage.

- Lashing points should exhibit pronounced plastic deformation prior to failure in order to detect damage due to overloading.

- Lashing points should have a design factor of 2 against breaking.

RUD/Endurequip will be displaying in the Brisbane Truck Show from 18-21 May 2023 at the Brisbane Convention Centre.

Visit us on Booth #380 (Plaza Level) to know more about our Lifting & Lashing Systems, Workshop Handling Solutions including Endurequip Portalift Hoists and Tyre Protection/Traction Chains.Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

If you want to know how the team at RUD can help you, please call 07 3809 1300 or fill out an enquiry form here.

Sources:

-

Importance of load securing in vehicles – Part 1

March 16th, 2023 | by endurequipWhen transporting goods or equipment over the road, it is critical to ensure that the goods or equipment is securely fastened. Insecure loads could lead to accidents including human life, and vehicle damage, and also risk to other road users. In addition to the financial and human costs of accidents; there are other significant risks such as liability and negligence claims, criminal prosecution, legal action, higher insurance premiums, and damage to the company’s reputation.

Load Securing

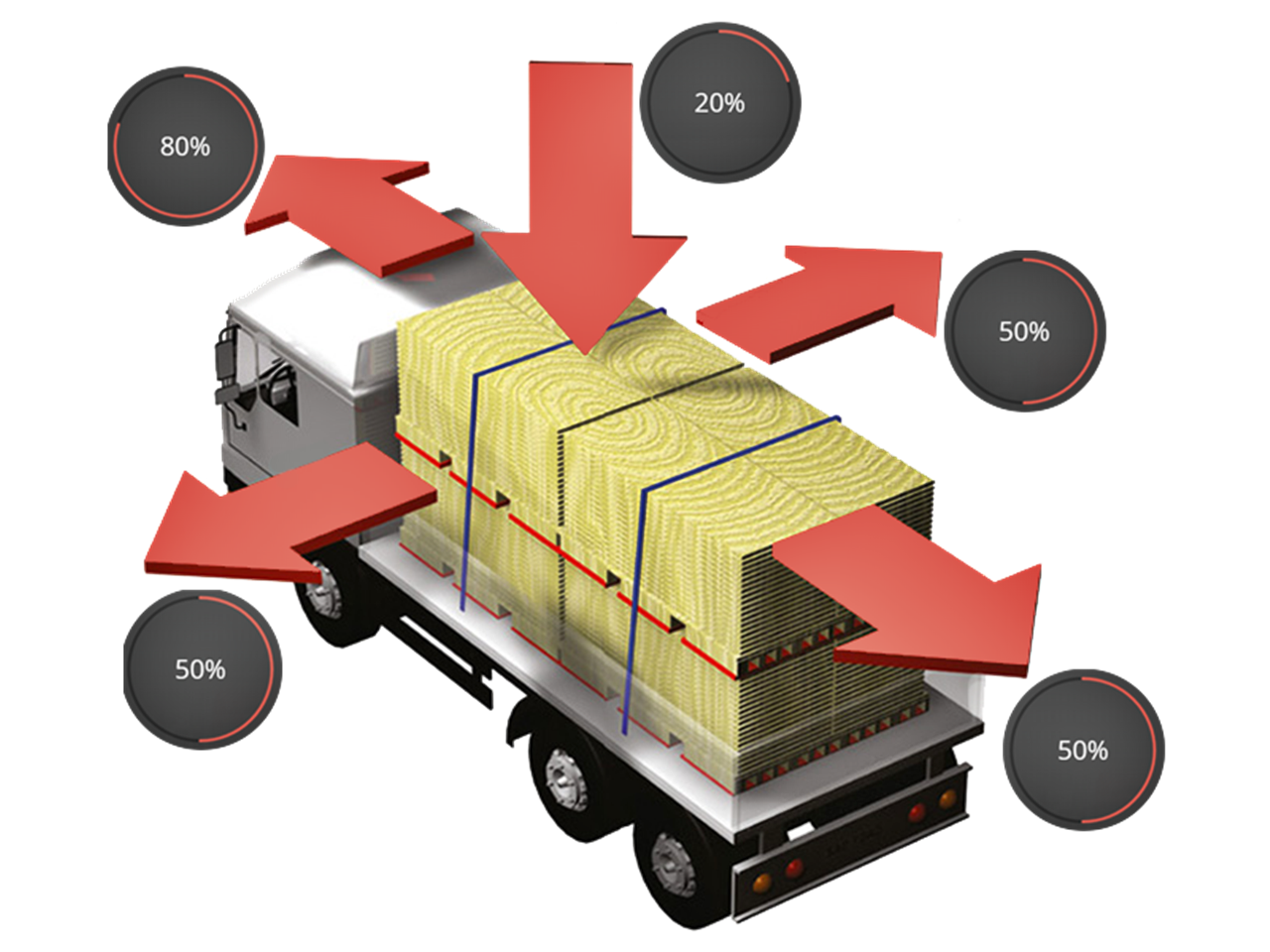

Cargo on a vehicle is subject to acceleration forces when the vehicle on which it is traveling accelerates, brakes, or changes direction. If the cargo on the vehicle is not securely fastened, this means the risk of the cargo moving forward, sliding backward, or tipping sideways is very high. Hence, when a vehicle brakes, the force of momentum will cause the unrestrained cargo to continue moving in its original (forward) direction and thereby cause significant risk of damage to the cargo itself, the vehicle, and possible personal injury to the driver or other road users.

Loaded vehicles are subject to 0.8g deceleration in forward movement, and 0.5g deceleration in both backward and lateral (sideways) directions*. For example, a cargo weighing 10 tonnes is subject to 8 tonnes of forward force and 5 tonnes either sideways or backward. Hence, the cargo must be secured to prevent damage, injury, and risks.

*Australian National Heavy Vehicle Register Load Restraint Guide 2018

Benefits of RUD Lashing Systems

RUD is the world leader and expert in lifting and lashing solutions. All RUD sling products are manufactured exclusively for lifting and load securing using cutting-edge technology. This is why our made-in-Germany innovative products set global standards for the lifting and lashing industry.

RUD offers a range of lashing points and lashing chains for optimal securing of cargo. Some of the popular RUD load-securing products for cargo transport are:

- L-VLBG-PLUS

- L-ABA

- LRBS-FIX

- LPW

- OPTILASH FIX and OPTILASH-CLICK

- ICE-Lashing Chain Classic and ICE-Lashing Ergo

- ICE-VSK-Endless Chain

Load securing hints for heavy cargo

One of the solutions to secure heavy cargo is to use RUD lashing chains in double strands.

Endless-Chain Lashing

What happens if there are no lashing points on the cargo to secure the load directly? Using a shackle to connect the lashing chain to unsuitable lashing points is risky because it exposes the shackle to bending stresses. The best option in such cases is to use an Endless Chain that has the same Lashing Capacity (LC) as a lashing chain. And if the chain is “doubled-up”, sharp edges will not cause any problems.

An ICE-Endless-Chain can be used with an ICE-Multi-shortening claw to form a closed chain.

The advantages of such a configuration are:

- The endless chain can be opened without tools and

- Is adjustable in its endless chain diameter.

Without Trucks Australia Stops. But when trucks need to go, Endurequip keeps them going!

Want to meet us?

RUD/Endurequip will be displaying in the Brisbane Truck Show from 18-21 May 2023 at the Brisbane Convention Centre.

Visit us on Booth #380 (Plaza Level) to know more about our Endurequip Hoists, Workshop Lifting/Handling Solutions and Tyre Protection/Traction Chains.Article copyright to RUD, this information is accurate at the time of publication and RUD Australia takes no responsibility for any errors inadvertent or otherwise.

Sources: